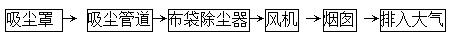

The environmentally friendly dust collector independently developed and produced by our company is equipped with a suction port on the pit wall and a top suction hood above the inertia ball roller outlet. The overflowing dust is collected by the suction hood and then enters the dust collection pipeline before entering the bag filter. After purification by the dust collector, the clean air is discharged into the atmosphere from the fan to the chimney, and the dust is intercepted by the dust collector and collected by the unloader. The entire system works under negative pressure. The location of the dust collector can be determined according to the actual situation of the demand side workshop. Namely:

3. Design of vacuum hood

The design of vacuum hood varies according to different process equipment, and the design principles are:

1) It does not affect the operation of workers.

2) Effectively collect the generated smoke and dust.

Based on the characteristics of the equipment and considering the convenience of the furnace operator, there is no vacuum hood installed on the wall suction port. The vacuum hood above the outlet of the inertia ball drum adopts a top suction method.

4. Calculation of generated air volume

According to the characteristics of the dust and the cross-sectional size of the vacuum hood, the required air volume in the pit of this sorting equipment is calculated to be about 22000m ³/h.

5. Design of the main suction pipe

Based on the total air volume and dust properties, the pipeline wind speed is taken as 20m/s. After calculation, the main pipeline has a diameter of 650mm, the branch pipeline has a diameter of 300mm, and the pipeline length is about 70 meters (including a 21 meter chimney). The resistance loss is about 1500Pa.

6. Design of dust collector

According to the nature of dust and the treatment requirements of exhaust gas, the dust collector can be designed as a DMC300-2450 single machine bag filter. Its design is as follows:

7. Selection of fan

Based on the total air volume and total resistance loss, the selected fan is a 4-68 8C30KW fan, with performance parameters as follows:

1) Filter area: 300m ²;

2) Air volume: 19404-33958m3/h;

3) Wind pressure: 1834-2619Pa;

4) Speed: 1400r/min;

8. Main parameters

1) Box size: 4330mm * 2200mm * 5860mm

2) Filter area: 300m ²

3) Fan power: 30KW

4) Bag specifications: φ133*2450mm

5) Fabric bag material: polyester knitted felt

6) Number of cloth bags: 300 pieces

7) Filter air speed: 1.2m/min

8) Dust removal efficiency: 99%

9) Equipment resistance: ≤ 1500Pa

10) Inlet concentration: ≤ 200g/Nm³

11) Export concentration: ≤ 30mg/Nm³

12) Number of pulse valves: 25 pieces

13) Pulse valve brand: Lanside

14) Pulse valve specification: 1.5-inch right angle pulse valve

15) Gas supply pressure: 0.5-0.7MPa

16) Gas consumption: 0.6m ³/min

17) Exhaust pipe height: 21m

18) Cleaning method: Online cleaning

Tel:13865492161 Mr. Chen

Email: 2313589758@qq.com

Address:Ningguo River Lixi Industrial Park, Anhui Province

Scan to view the mobile website

COPYRIGHT © 2026 Anhui Ningguo Longsheng Machinery Equipment Technology Co., Ltd 皖ICP备2025074313号-1 sitemap technical support:Chengguang Network