The cross box casting shell type production line is a continuous casting production line suitable for casting and forging balls with a diameter of less than 40. It has a high degree of automation, reduces labor intensity for workers, and lowers production costs. The entire line covers an area of about 350m ². If the shell type requirements of the production line are met, three GX-KXJ-70 shell type core shooting machines need to be equipped.

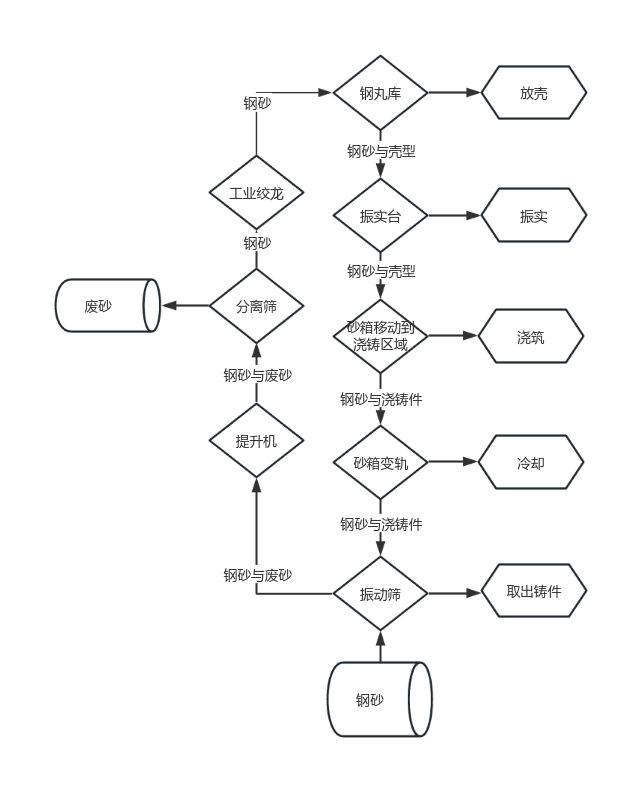

Production line process

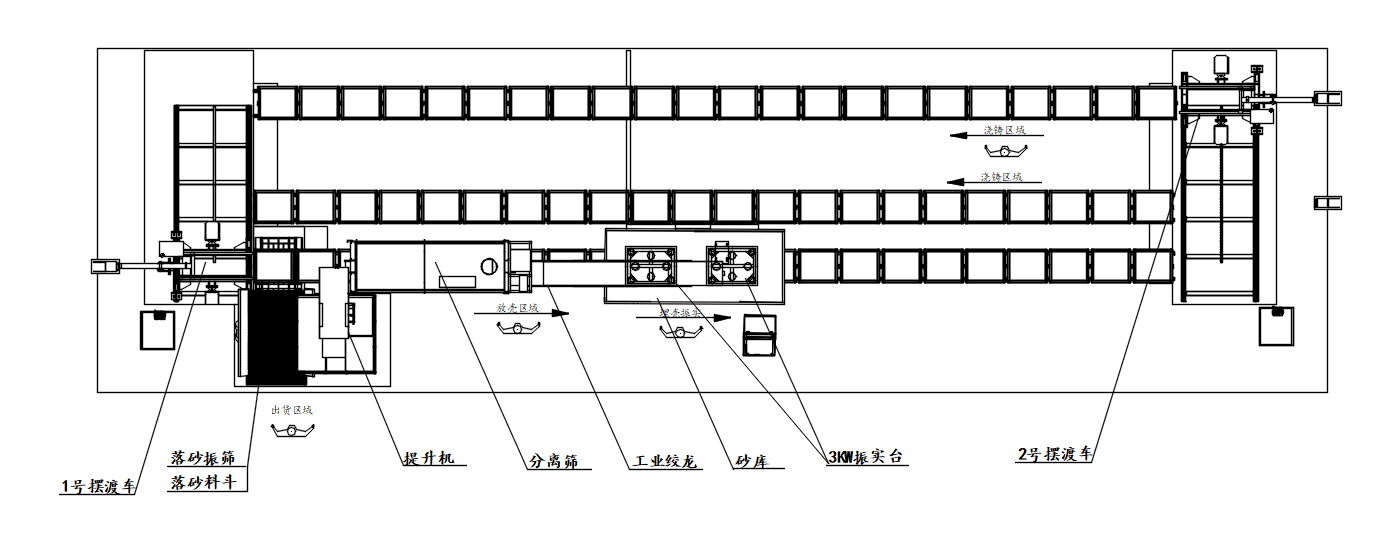

Figure 1- Equipment Layout

(1) After completing the shell filling in the shell area, run the pushing cylinder to move the sand box above the compaction table, and activate the compaction table button (foot pedal) for compaction;

(2) A sand box with a shell shape is used for pouring in the pouring area;

(3) The poured shell is gradually cooled in the cooling section through the operation of the shuttle transmission;

(4) The trolley carrying the cooled castings enters the flipping box and vibrating screen station, which is the shipping area. The castings and fixtures are separated, and the waste sand and steel balls are transported to the feeding port of the hoist by the winch. Then, they are transported to the separation screen by the No. 1 hoist for waste sand and steel balls separation. The steel balls screened by the separation screen are transported to the steel ball warehouse by the winch for recycling.

The replacement of sand boxes on the flipping machine and the completion of flipping should be considered as one cycle, taking into account factors such as manual and electric furnace work cycles, cooling time requirements between casting and shipment, pouring scale, etc. The cycle can be reasonably adjusted according to your company's requirements to improve production rate.

Tel:13865492161 Mr. Chen

Email: 2313589758@qq.com

Address:Ningguo River Lixi Industrial Park, Anhui Province

Scan to view the mobile website

COPYRIGHT © 2026 Anhui Ningguo Longsheng Machinery Equipment Technology Co., Ltd 皖ICP备2025074313号-1 sitemap technical support:Chengguang Network