The 840 ball casting production line can meet the annual production demand of 10000 tons. This production line is suitable for the production of various specifications of steel balls with diameters ranging from 40 to 130; Specifically, as follows:

(1) Design Guidelines for Ball Casting Production Line

1. The GXLS-840-80 ball casting production line is the fifth generation automatic ball casting production line independently developed by our company. The 840 ball casting production line can meet the annual production demand of 10000 tons (10 hours per shift, 300 days/year). This production line is suitable for casting balls of various specifications: φ40-130, Casting ball material: high chromium alloy casting ball, medium chromium alloy casting ball, low chromium alloy casting ball, CADI grinding ball.

2. Production line technical standards: automation+intelligence+digitization, with safety and quality cost as the core of overall design, optimized design based on the casting ball production process, reasonable layout of production equipment, environmental protection equipment, raw materials, auxiliary materials, waste and finished products, etc., to create a green casting production workshop.

3. Equipment working environment temperature:- 25 ℃~+50 ℃.

4. There are 4 job positions along the entire line (excluding auxiliary workers).

(2) Technical parameters related to the production line

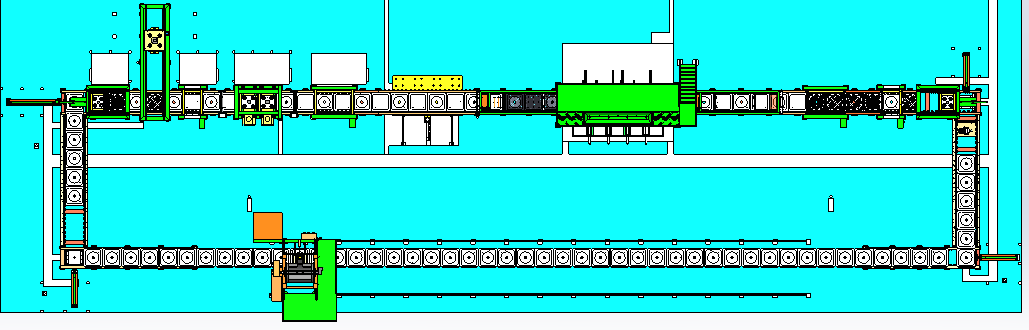

1. Maximum external dimensions: 45m in length and 14m in width (specific dimensions can also be designed according to the needs of the workshop).

2. Action modes: hydraulic drive, mechanical drive, and pneumatic drive.

3. Can meet the simultaneous production of two different specifications of cast balls.

4. Control mode: PLC automatic control system for the entire line.

5. The fastest no-load operation is 50 "/cycle, normal production is 50-70"/cycle, sand shooting time is 5-6 seconds, and sand mold solidification time is 13-23 seconds.

6. Total power of the entire line: 140KW. (including pouring machine, excluding air compressor)

7. Mold heating and cooling method: natural gas or gas heating (infrared intelligent heating and cooling system) is set at the same workstation; When the mold temperature exceeds the process temperature, the cooling system automatically starts to cool the mold, and the amount of water mist and cooling time can be adjusted arbitrarily. When the mold temperature is too low, the heating system automatically ignites to heat the mold, using natural gas or coal gas heating. The track in this area is water-cooled, which improves the service life of the rollers.

8. Gas consumption: 4.5 cubic meters.

9. Equipped with intelligent fault query and fault alarm.

10. Casting method: servo casting machine (user selected).

11. Mold: The outer dimensions of the lower mold are 840 * 840mm, and the upper mold is 840 * 835mm. The weight of the mold is about 850kg per cycle (average value of 50-120), with a total of 80 mold stations in the entire cycle. At least 70 molds can be used for normal production, and the practical life of the mold is 3 years. This mold is designed for iron mold sand coating process, with a sand coating thickness of 3-6mm, suitable for casting balls of various materials. The mold template adopts electric heating method, and the mold temperature is detected by sensors. The PLC system automatically regulates and integrates the solidification time of the molding sand.

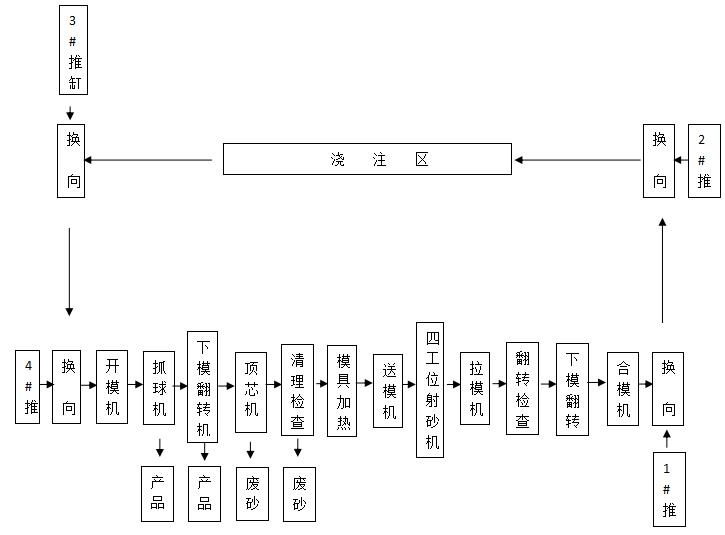

Operating principle of production line (as shown in the following figure)

Tel:13865492161 Mr. Chen

Email: 2313589758@qq.com

Address:Ningguo River Lixi Industrial Park, Anhui Province

Scan to view the mobile website

COPYRIGHT © 2026 Anhui Ningguo Longsheng Machinery Equipment Technology Co., Ltd 皖ICP备2025074313号-1 sitemap technical support:Chengguang Network